Choose the Most Suitable Tint Pros Vinyl Wraps Options for Automobiles, Trucks, and SUVs

Choose the Most Suitable Tint Pros Vinyl Wraps Options for Automobiles, Trucks, and SUVs

Blog Article

The Ultimate Overview to Picking the Right Plastic Wraps for Your Job

Picking the ideal vinyl wrap for your job requires a nuanced understanding of numerous aspects that affect both looks and functionality. As you browse these factors to consider, it becomes clear that the course to an effective vinyl wrap project is layered with crucial choices that merit additional expedition.

Sorts Of Plastic Wraps

When choosing plastic wraps, understanding the different types available is vital. Plastic covers can be extensively classified into two primary kinds: cast vinyl and calendared vinyl. Cast plastic is known for its exceptional high quality, adaptability, and durability, making it perfect for complicated surfaces and lasting applications. It is created by casting fluid plastic onto a film, causing a thinner, more conformable product that adheres well to curves and contours.

On the other hand, calendared plastic is made by a procedure that involves rolling and stretching plastic sheets. This kind is usually thicker and cheaper than cast plastic, making it suitable for level surface areas and temporary applications. While calendared plastic provides a cost-effective service, it might not execute also on elaborate styles or in extreme weather problems.

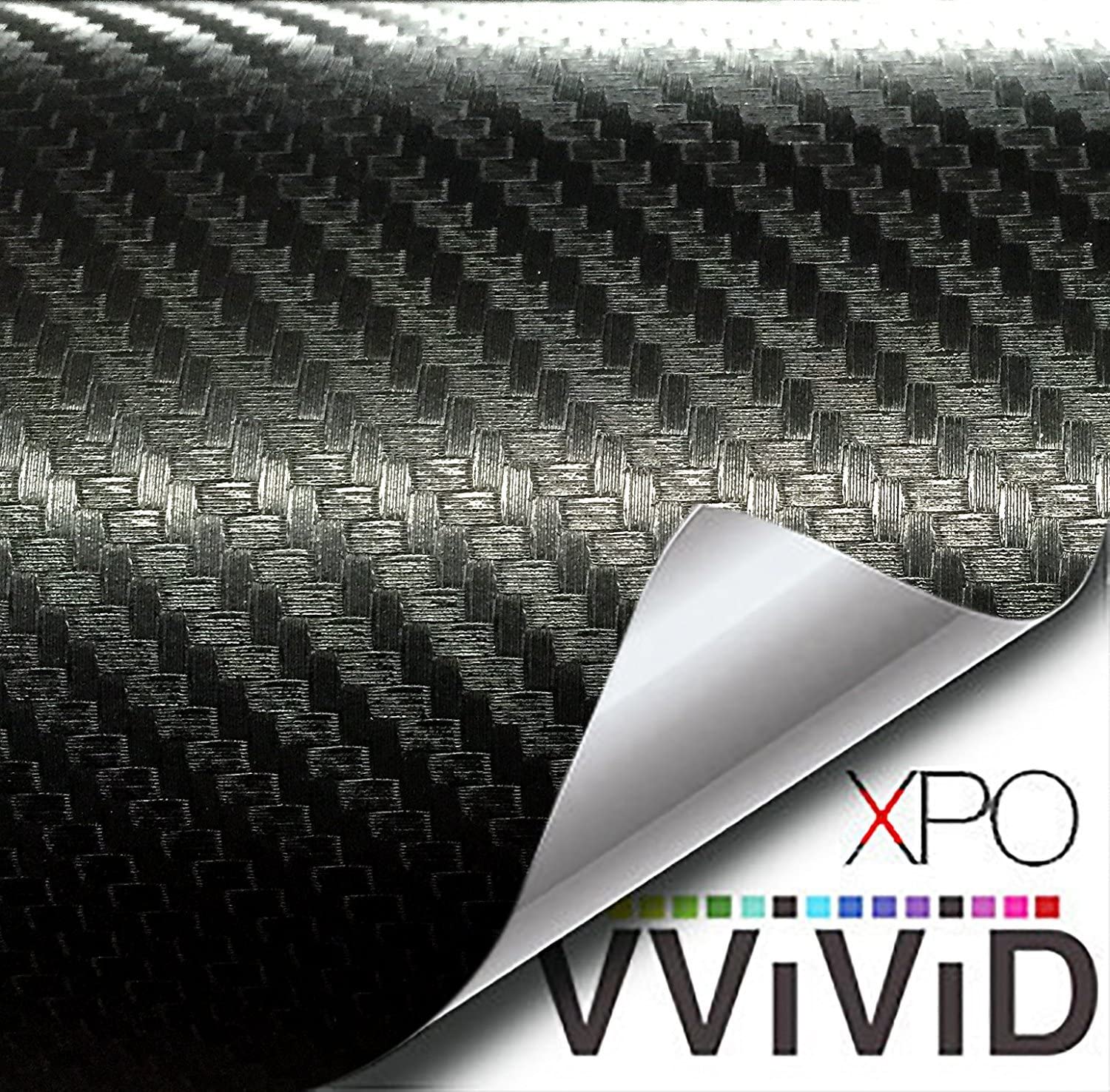

Furthermore, specialized plastic covers are offered, consisting of metal, matte, and distinctive surfaces, which can enhance looks while providing distinct qualities. Recognizing these kinds of plastic covers will allow you to make educated decisions based on your job needs, making certain optimal lead to both appearance and durability.

Selecting the Right End Up

Picking the suitable surface for your vinyl cover is a vital element that can substantially impact the overall aesthetic and capability of your task. Vinyl wraps come in a range of coatings, each offering distinctive visual effects and performance attributes. The most typical coatings consist of gloss, matte, satin, and textured choices.

A gloss finish supplies a high-shine surface area that improves shade vibrancy and deepness, making it perfect for appealing designs. Nevertheless, gloss finishes may be much more prone to scratches and finger prints. In comparison, a matte finish provides a subdued and sophisticated look, decreasing glare and imperfections. This coating is typically chosen for an extra downplayed look but can be less immune to dust and discolorations.

Satin surfaces strike a balance between matte and gloss, offering a soft shine that adds beauty without frustrating the design. Textured coatings, such as cleaned steel or carbon fiber, can add a special responsive component, improving the aesthetic appeal of your task.

Eventually, your choice of surface should align with the preferred aesthetic and the setting where the cover will be applied. Think about durability, upkeep, and the specific application to ensure ideal results.

Installment Techniques

Exactly how can you guarantee a perfect application of vinyl covers? A tidy, smooth surface is crucial for ideal results.

Next, gather needed tools such as a warm weapon, squeegee, and utility knife. These devices will certainly aid in applying the vinyl smoothly and trimming excess product. When applying the wrap, work in areas, beginning with one edge and delicately spreading out the vinyl click for info while using the squeegee to get rid of air bubbles.

Heat can be advantageous in this procedure; it makes the vinyl more flexible, enabling it to satisfy curves and contours easily. Workout perseverance and stay clear of rushing, as this can cause misalignment or bubbles. In cases of difficult areas, such as around edges or manages, take into consideration making use of a method called "tack and stretch" to develop a smooth fit.

Maintenance Tips

To keep the stability and look of vinyl covers, normal care is essential. Begin by cleaning the wrapped surface with a gentle soap option and a soft sponge or microfiber cloth. Stay clear of severe chemicals, as they can damage the plastic. Tint Pros Vinyl Wraps. It's ideal to clean your wrap every two weeks to get rid of dust, crud, and contaminants that can cause the cover to lose its gloss.

Dry the surface area completely after washing, as water spots can come to be irreversible if entrusted to completely dry naturally. For included defense, think about applying a specialized plastic cover sealer, which can help maintain the color and avoid fading from UV direct exposure.

Additionally, avoid auto parking in direct sunlight for extensive periods, as long term exposure can result in discoloration and degradation of the wrap. Utilize a vehicle cover or park in shaded locations. if feasible.

Consistently check the wrap for any signs of training or damage. Resolve them quickly to avoid more wear and tear if you observe any kind of issues. Complying with these maintenance ideas will guarantee that your plastic cover remains vivid and prolongs its life-span, ultimately boosting the visual appeals of your job.

Common Blunders to Avoid

When it comes to plastic wraps, avoiding common risks can substantially impact both the application procedure and the durability of the cover. Appropriate cleaning and priming are important to make sure that the vinyl sticks effectively.

An additional typical mistake is choosing the wrong sort of plastic for the details application. Various tasks call for different materials; for example, a vehicle cover ought to utilize cast vinyl for sturdiness, while a short-term sign might be properly offered by calendared plastic.

Insufficient warm application throughout installment can also lead to issues such as wrinkles and incorrect adherence. Utilizing a heat weapon at the proper temperature level is critical for dealing with the vinyl, specifically in difficult areas like contours or edges.

Finally, overlooking post-installation treatment can reduce the life expectancy of the cover. Failing to adhere to upkeep standards, such as staying clear of extreme chemicals or abrasive cleansing tools, can result in damage. By guiding clear of these mistakes, you can improve the efficiency and aesthetic allure of your vinyl cover task.

Verdict

Finally, picking the appropriate plastic cover demands cautious factor to consider of numerous aspects, consisting of the kind of plastic, surface options, and setup techniques. Proper prep work and adherence to finest methods are important for attaining optimal outcomes and ensuring the long life of the cover. By avoiding typical mistakes and making notified choices, people can effectively boost the visual appeal and longevity of their projects with the tactical use plastic wraps.

Vinyl covers like this can be broadly categorized into 2 major kinds: cast plastic and calendared vinyl.On the other hand, calendared vinyl my company is produced by a procedure that includes rolling and stretching plastic sheets.Selecting the suitable coating for your plastic cover is a vital element that can significantly impact the overall aesthetic and performance of your job.When it comes to vinyl wraps, preventing typical mistakes can considerably impact both the application process and the longevity of the cover.In conclusion, selecting the appropriate plastic wrap requires mindful consideration of different factors, including the type of vinyl, finish options, and setup techniques.

Report this page